One major benefit is that laminated glass with minor impact damage can be repaired with a special clear adhesive resin.

Some additional benefits of laminated glass are that it reduces transmission of high-frequency sound (soundproofing) and it blocks 97% of ultraviolet radiation. Even if the glass does break on either side the pieces will stay together resulting in a spider-web pattern.

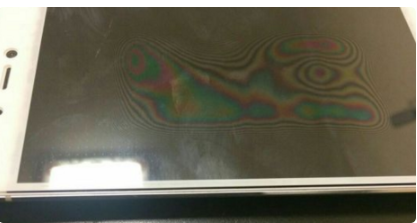

If the glass is dealt with a high-intensity impact, one side of the glass can shatter without causing the other side to shatter. When laminated glass was originally invented it was designed for use in car windshields to reduce the number of injuries in car accidents. The laminated glass has just enough give and stick in it to hold the glass in place if it were to break. The plastic layer of the film does give the glass a stretchable quality but don’t imagine the glass stretching like a rubber band. Laminated glass can be made stronger by adding layers making the end product thicker. After this, the glass is heated under pressure to create a finished bound product. The set of glass is treated through a process intended to expel air pockets and then it is heated for an initial round of melting. Laminated glass is made of two pieces of regular or tempered glass sandwiched around a layer of clear plastic film (PVB). **Consult your local building guides to confirm these parameters.

#Tempered glass remove halo effect windows#

Tempered glass and laminated glass are two of the most common types of safety glass. If you’re in the process of building or upgrading your home you may have already been asked to choose some safety glass for some of your windows and doors.

0 kommentar(er)

0 kommentar(er)